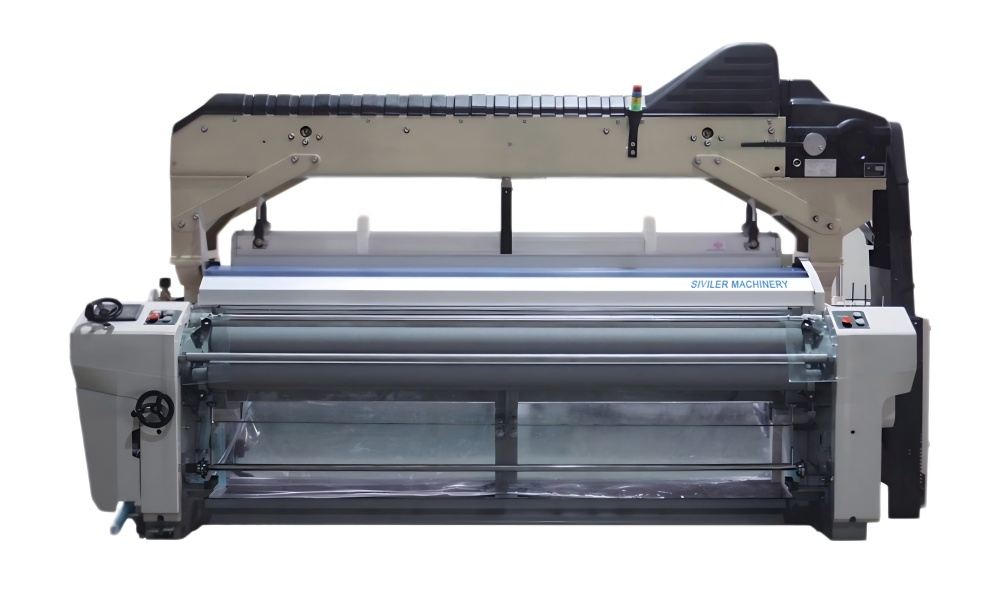

SWL822 design based on Tsuda Koma ZW-303 series water-jet loom,which is optimizing the main component and frame structure,improving the beating-up,let-off mechanism and take-up mechanism,installing assistant device on let-off mechanism,all of this ensure the running stably and reduce vibration and noise,increase efficiency and enlarge the weaving range.

SWL822 designed a more robust fabric support structure and a more tensile and anti slip take-up roller structure. A stable weave not only reduces the generation of various fabric patterns, but also makes high tension and high weft density fabrics easier to weave.

Widen the middle plate, increase the force bearing area of the machine, and make the machine operate more stably. Enhanced crossbeam support makes the frame more stable and reduces vibration.

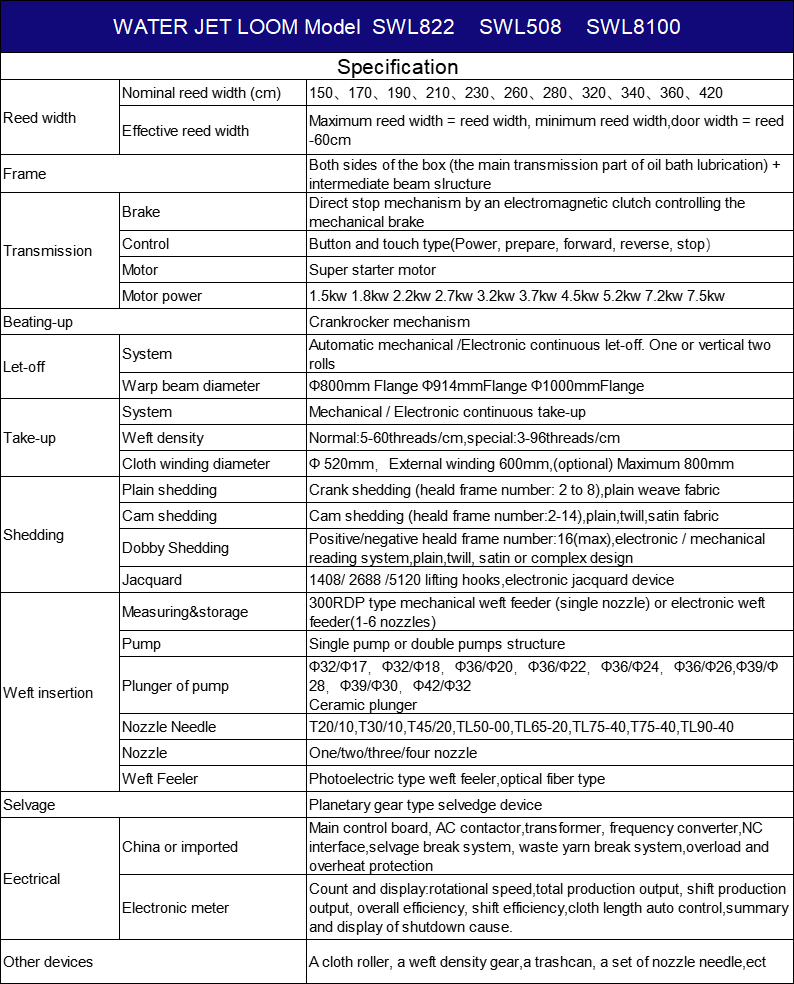

◆ Optional:mechanical let-off,mechanical take-up,electronic let-off,electronic take-up

◆ Optional:RDP mechanical measuring &storage device,1-4 nozzle electronic free weft selecting

◆Configurable shedding devices:crank shedding;cam shedding;dobby shedding;jacquard shedding

◆ Optional reed width:135,150,170,190,210,230,260,280,300,320,340,360,420CM

◆ The weft density range:4-96threads/cm(according to actual weft yarn specifications and fabric weave)

◆ Maximum speed:1000RPM(according to actual weft yarn specifications and fabric weave)

◆Heald frame number:crank shedding 2-8 pieces;cam shedding 2-14 pieces;dobby shedding 16 pieces

◆Install power:1.5kw-7.5kw

Apply yarn types:oxford fabric, shirt fabric, chiffon, georgette, four-sided elastic, luggage fabric, polyester taffeta, etc.